5 Hidden Costs of Lost Energy

-

Best Seller

BLASTBAG™ SOLO

Most used BLASTBAG™ in the world with dual speed inflation.

-

BLASTBAG™ EVO

BLASTBAG™ with non-flammable aerosol propellant.

-

BLASTBAG™ AERO

Air-operated BLASTBAG™ for efficient, safe mining operations.

-

BLASTBAG™ ACE II

Safe, non-toxic, chemical-reactive BLASTBAG™.

-

BLASTBALL™

Air-operated, robust plugging device for optimal underground mining.

-

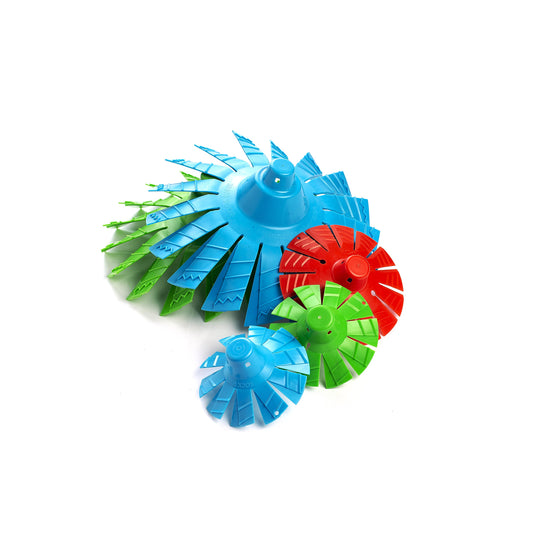

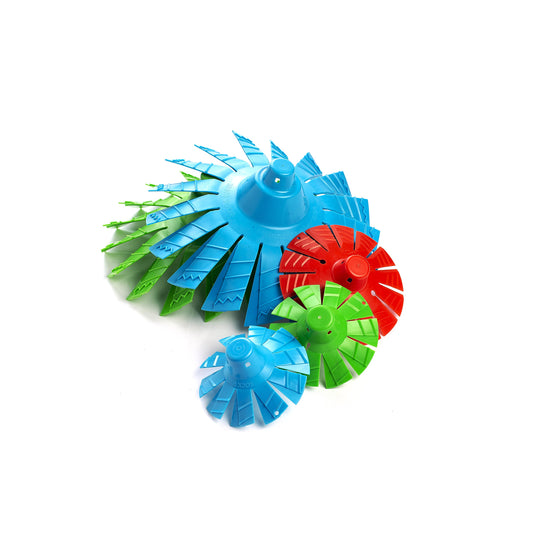

ROCKRIVETS

Friction-based retention spider plug

-

SLUMPSTOPPA

Maintains emulsion integrity in underground mining operations

-

BLASTSHIELD™ Plus Blasthole Liner

Ultra-high strength liner for waterlogged blast holes.

Ultra-high strength liner for waterlogged blast holes.

Vendor:MTi USA