Collection: Stemming Plugs

A stemming plug is a device placed in the upper portion of a blast hole to confine explosive gases, reduce energy loss, and improve fragmentation by holding the stemming material firmly in place during a blast.

-

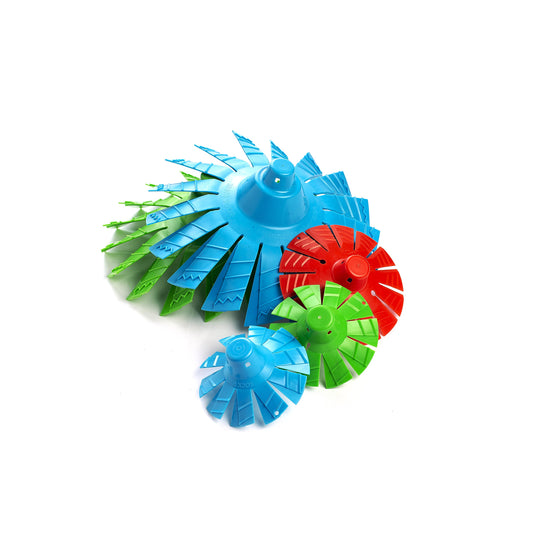

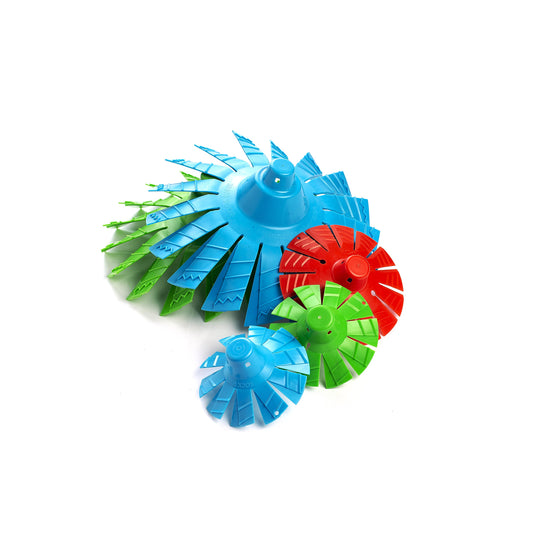

ROCKRIVETS

Friction-based retention spider plug

-

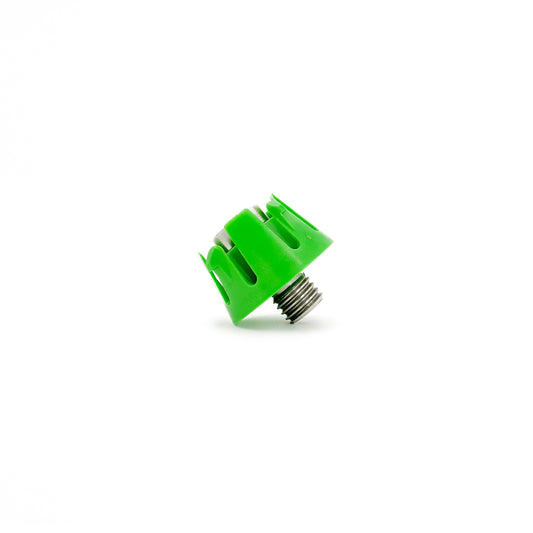

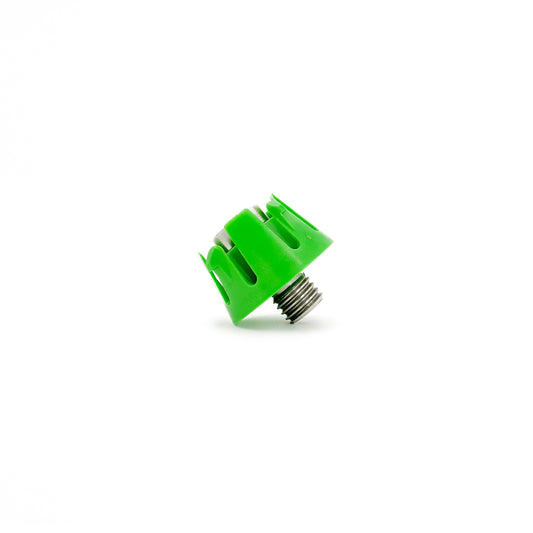

ROCKRIVET Connector

Load pole connector for easy installation of ROCKRIVET and SLUMPSTOPPA.

-

BLASTBALL™

Air-operated, robust plugging device for optimal underground mining.

-

SPRINGLOCK

Ensures secure explosives placement in tunneling operations.

Stemming Plugs

FAQ's - Stemming Plugs

How do stemming plugs improve overall blast performance?

Stemming plugs create a tight seal in the blasthole, helping explosives work more efficiently. They can, combined with stemming, improve energy retention in the borehole, reduce airblast, and reduce stemming ejection so crews get safer, more consistent blast outcomes.

Why are stemming plugs important for mining and quarry operations?

They help stabilize the stemming column, control gas release, and deliver more predictable fragmentation. This improves blast quality across open pit, underground, and quarry environments.

What are the key advantages of using stemming plugs?

- Improve stemming retention/confinement

- Reduce airblast

- Support consistent fragmentation

- Help stabilize stemming in variable geology

- Increase safety across mining and quarry operations

- Can be used to create air decks in smaller diameter holes

How do I choose the right stemming plug for my site?

Select a plug based on your borehole diameter, geology, and blasting objectives. This collection provides options suited for underground, open pit, construction blasting, and quarry operations — allowing your team to match the plug to your specific needs.

In open pit applications, ROCKRIVETS™ are typically used. In underground operations, ROCKRIVETS™ are typically used unless you don't need to support a lot of weight, then the MITIPLUG™ (Pilgrim Hat) can be used.

What blasting applications benefit the most from stemming plugs?

They are ideal for production blasting, perimeter control, presplit work, and general shot optimization. They help achieve cleaner benches, better wall control, and improved fragmentation.

Do these stemming plugs work in different ground conditions?

Yes. These stemming plugs perform reliably in hard rock, soft rock, and mixed geology. They maintain a secure seal so your blast pattern remains consistent even in challenging ground.

Learn more

View all-

Reduce Ore Loss & Dilution in Mining

Discover how a major South American copper mine cut ore loss by 36.6% and saved over $42,000 using MTi’s BLASTBAG™ technology.

Reduce Ore Loss & Dilution in Mining

Discover how a major South American copper mine cut ore loss by 36.6% and saved over $42,000 using MTi’s BLASTBAG™ technology.

-

Flyrock Reduction in Surface Blasting

BLASTBAG™ air decking cut flyrock incidents to near zero and reduced charge per hole by 33 lbs, enabling safer blasting at a West African gold mine.

Flyrock Reduction in Surface Blasting

BLASTBAG™ air decking cut flyrock incidents to near zero and reduced charge per hole by 33 lbs, enabling safer blasting at a West African gold mine.

-

Solving Hard Digging

MTi’s BLASTBAG™ cut dig times by 21% and reduced costs by 8% at a South Kalimantan mine.

Solving Hard Digging

MTi’s BLASTBAG™ cut dig times by 21% and reduced costs by 8% at a South Kalimantan mine.