When a blast behaves unpredictably, it may not be caused by timing or geology. Sometimes, it’s as simple as the choice of stemming plugs.

Here are 7 clues you might be using the wrong plug:

1. Incorrect Blasthole Plug Size for the Hole

Worn bits, soft ground, and swelling can change the designed hole diameter. If the plug doesn’t match the borehole size, it won’t create proper friction or confinement. Undersized plugs can slip, while oversized plugs may be difficult to install correctly.

2. Stemming Ejection During Blasting

A plug with poor holding strength can eject under gas pressure, reducing blast efficiency and causing energy loss. This often results in flyrock and poor fragmentation.

3. Stemming Plug Flipping or Tilting in the Hole

Inconsistent hole walls, over-drilling, or uneven collars can cause a plug to flip sideways. When a plug isn’t seated flat, it cannot seal or hold effectively.

4. Stemming Plug Hanging Up in Cracks or Voids

Natural fractures, cavities, or seams can cause a plug to stop prematurely or slip during installation. When the plug hangs above the intended depth or sticks where it shouldn’t, the stemming height and burden control become compromised. Learn more about controlling blast energy here.

5. Improper Deck Support or Wrong Tools

Some plugs aren’t designed to support multiple explosive decks. If the plug fails, the designed spacing between decks collapses, leading to performance loss, overbreak, or oversize.

6. Poor Sealing and Stemming Leakage

If the plug doesn’t seal tightly, fines or explosives can migrate past it. This reduces the explosive column or stem height and changes the designed load profile of the hole.

7. Interference with Detonator Lines

Using plugs without proper line clearance can pinch, cut, or misalign downlines. This increases the risk of cutoffs or delayed initiation issues.

Takeaway

The stemming plug is small but can control a huge part of blast performance. Good confinement gives you predictable fragmentation, safer walls, and better overall use of energy.

<

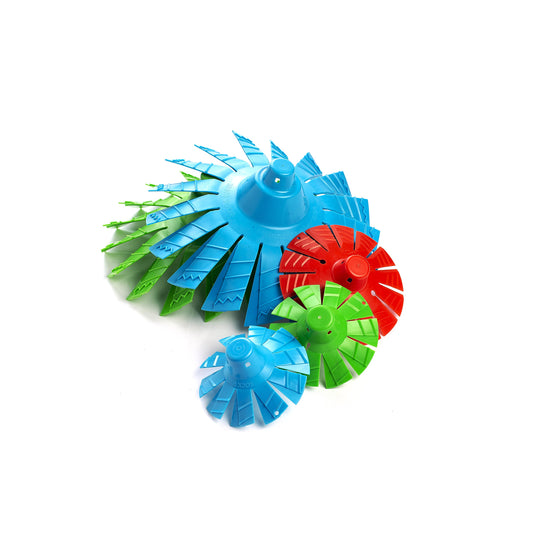

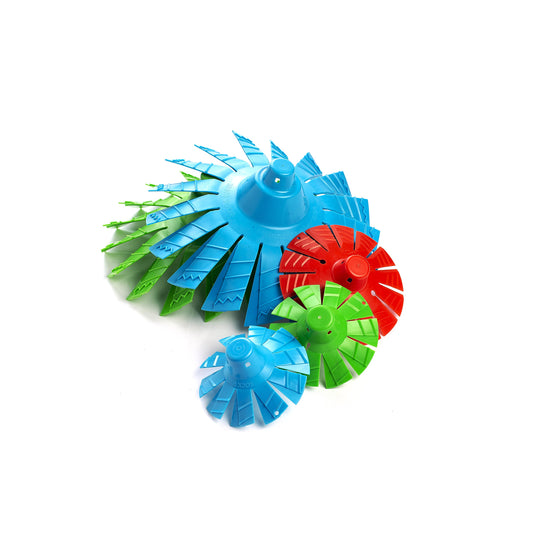

MTi GROUP builds plugs designed to install easily and grip consistently in real-world applications. Tools like ROCKRIVET™ and MITIPLUG™ help crews lock in their stemming, support air decks, and keep energy where it belongs. You can find them above or reach out to sales@mtigroup.us for more information. Also, follow us on LinkedIn!