Although the true performance of blast isn't fully assessed until it's been mucked, the muck pile sure can be telling of how the shot performed, if you know what to look for, the muck pile can tell you about fragmentation, throw, burden problems, and stemming failures before the next pattern is drilled.

Why the muck pile matters after blasting

The muck pile is the fastest feedback you'll get after a blast. No instruments. No reports. Just the rock in front of you.

An evenly displaced muck pile usually means the energy stayed in the hole. A messy pile with oversize or uneven throw often points to issues with burden, spacing, or poor confinement.

If the pile loads clean and breaks evenly, the blast probably worked.

What the muck pile tells you about fragmentation

Start by looking at fragment size.

- Lots of oversize usually means lost energy from poor face burden, cracks, or poor stemming.

- Too many fines can point to excess energy or timing issues.

- Consistent fragment size usually means the rock broke as planned.

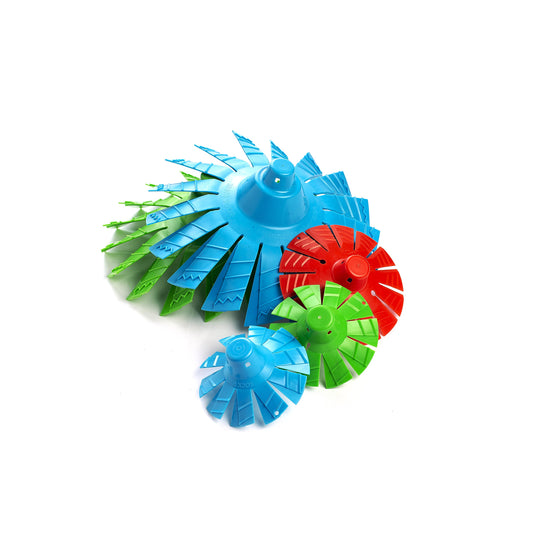

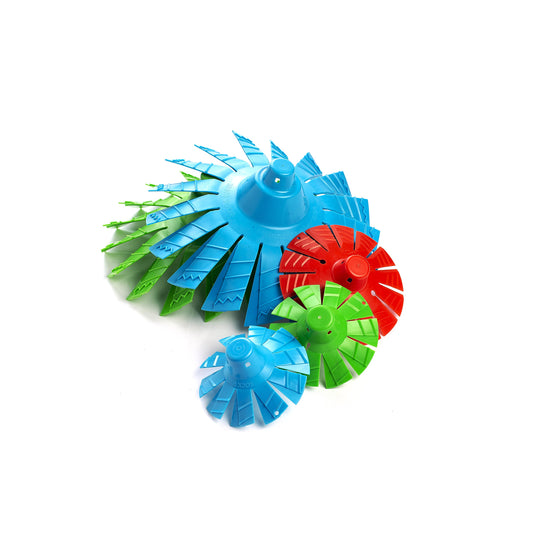

Good confinement matters. When explosive gases escape through cracks, voids, or inefficient stemming, they stop breaking rock. Products like BLASTBAG™ and ROCKRIVET™ partnered with stemming can help seal the borehole, so energy stays where it belongs.

Video: Example of a muck pile after blasting, showing fragmentation and overall pile shape.

Common blast problems seen in the muck pile

Overbreak

Rock thrown too far or broken behind the face. Often caused by tight burden or excessive energy.

Underbreak

Large boulders and toes left behind can be a result of low energy or too large burden/spacing.

Common reasons for low energy are wet holes, cracks/voids, or inefficient stemming.

Uneven throw

One side of the muck pile travels farther than the other. This usually points to loading inconsistency, or insufficient burden.

Misfires

Unbroken columns of rock or visible hole outlines in the muck pile can indicate a misfire from poor timing, or a cut detonator.

How to improve muck pile results on the next shot

- Confirm hole depth, burden/spacing, and charge placement using MITIMEASURE™, Depth Gauge, or Driller's Tape.

- Inspect holes before loading with a Borehole Camera when encountering fractured or voided ground.

- Use proper stemming to seal the hole and retain energy. Sometimes stemming plugs such as BLASTBAGS™ or ROCKRIVETS™ can enhance stemming.

- Watch for burden and spacing changes across the bench, especially along the face and back rows.