SLUMPSTOPPA™ is a bottle brush–style uphole retention device used in emulsion blasting to control slumping during loading.

In underground operations, emulsion can slump back in upholes while charging. That wastes product, creates mess, and makes collar height inconsistent. SLUMPSTOPPA™ is inserted into the blasthole during loading to help retain the emulsion column where it belongs.

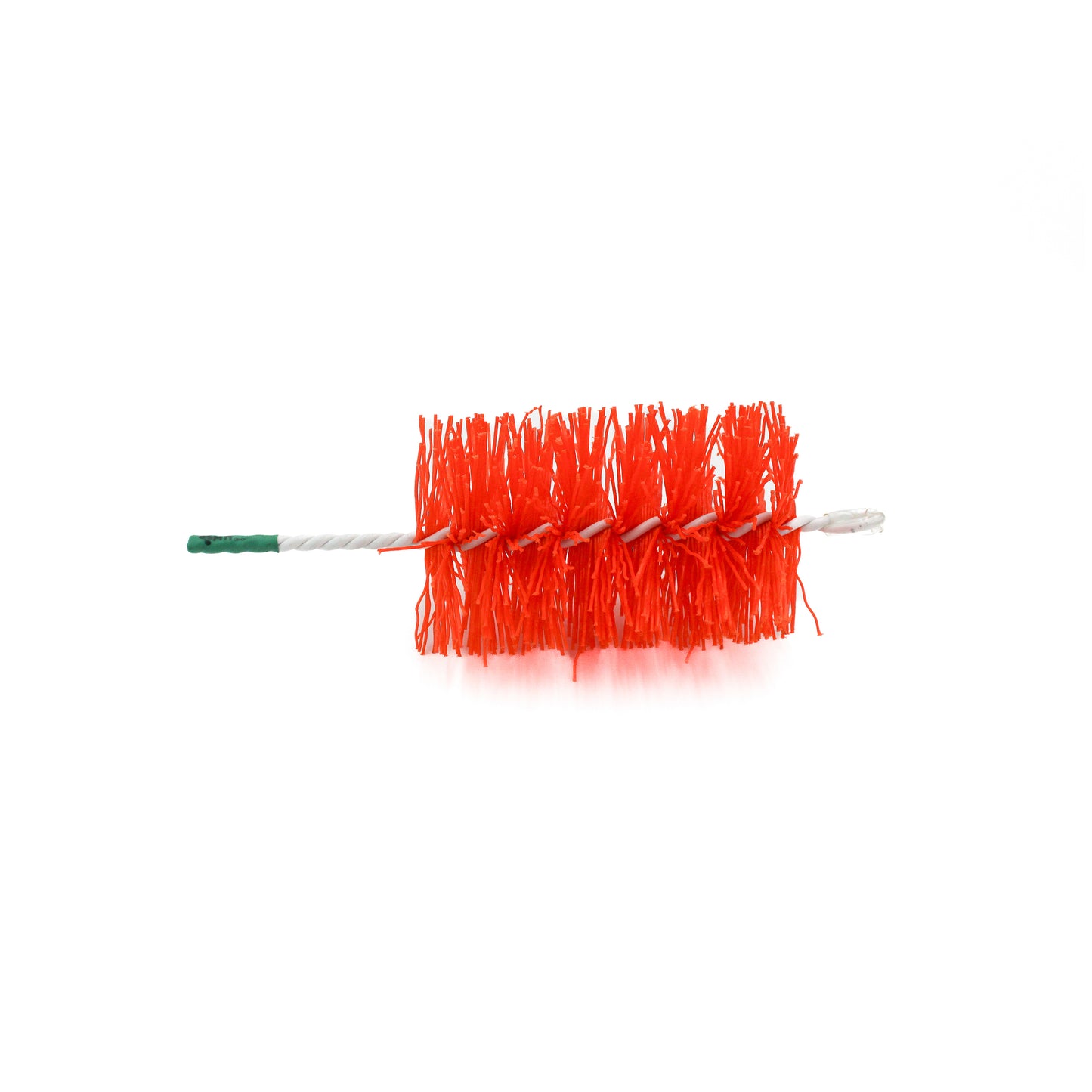

On site, many blasters call it a bottle brush. And visually, it looks similar. But its job isn’t cleaning. It’s charge control.

The polymer bristles fold back during insertion, allowing the device to be pushed several meters into the hole. Once in place, the bristles help hold the emulsion in position while still allowing gassing to occur. This helps maintain correct collar height and improves loading consistency.

SLUMPSTOPPA™ is commonly used in underground emulsion blasting where clean loading, reduced waste, and better housekeeping matter. It’s resistant to emulsion chemicals and designed around global best practice for explosive loading.

Used for:

- Emulsion blasting in underground mining

- Uphole charge retention

- Controlling emulsion slumping during loading

- Improving collar height consistency

- Reducing wasted emulsion and cleanup

Key features:

- Bottle brush–style bristle design

- Flexible polymer bristles with stainless steel spine

- Allows emulsion gassing while retaining charge

- Resistant to emulsion chemicals

- Designed to reconcile with AS 2187.2 best practice

If emulsion slumping is an issue during loading, SLUMPSTOPPA™ provides a simple, proven way to keep the charge where it needs to be.

Terms & Conditions

Terms & Conditions

Non-Sparking

Case Studies

View all-

Reduce Ore Loss & Dilution in Mining

Discover how a major South American copper mine cut ore loss by 36.6% and saved over $42,000 using MTi’s BLASTBAG™ technology.

Reduce Ore Loss & Dilution in Mining

Discover how a major South American copper mine cut ore loss by 36.6% and saved over $42,000 using MTi’s BLASTBAG™ technology.

-

Flyrock Reduction in Surface Blasting

BLASTBAG™ air decking cut flyrock incidents to near zero and reduced charge per hole by 33 lbs, enabling safer blasting at a West African gold mine.

Flyrock Reduction in Surface Blasting

BLASTBAG™ air decking cut flyrock incidents to near zero and reduced charge per hole by 33 lbs, enabling safer blasting at a West African gold mine.

-

Solving Hard Digging

MTi’s BLASTBAG™ cut dig times by 21% and reduced costs by 8% at a South Kalimantan mine.

Solving Hard Digging

MTi’s BLASTBAG™ cut dig times by 21% and reduced costs by 8% at a South Kalimantan mine.

Learn

View all-

Can You Diagnose Blast Issues By Simply Looking...

Learn how to read the muck pile after blasting to spot fragmentation, throw, and stemming issues before the next shot.

Can You Diagnose Blast Issues By Simply Looking...

Learn how to read the muck pile after blasting to spot fragmentation, throw, and stemming issues before the next shot.

-

Presplit Blasting: What It Is & Why It Matters

Presplit blasting uses a tight row of light charges to control overbreak and protect your final wall, leaving a cleaner and safer face.

Presplit Blasting: What It Is & Why It Matters

Presplit blasting uses a tight row of light charges to control overbreak and protect your final wall, leaving a cleaner and safer face.

-

7 Clues You’re Using the Wrong Stemming Plugs

A lot of blast issues trace back to one small part—the stemming plug. Here are 7 clues yours might be failing and costing you performance.

7 Clues You’re Using the Wrong Stemming Plugs

A lot of blast issues trace back to one small part—the stemming plug. Here are 7 clues yours might be failing and costing you performance.

Subscribe to our emails

Be the first to know about new collections and exclusive offers.